Pre-Engineered Buildings: Building Certainty into Modern Construction

In the world of industrial and commercial construction, one fact is becoming increasingly clear: pre-engineered buildings (PEBs) are no longer a niche alternative but the mainstream choice for modern steel construction. From logistics parks and manufacturing hubs to large-scale expansions, businesses across industries are embracing PEBs because they offer a rare combination of speed, performance, cost efficiency, and sustainability. Yet, while the demand is rising, success still depends on one decisive factor—choosing the right manufacturing partner.

Why Choosing the Right Manufacturer Matters

Selecting a manufacturer is far more than a procurement decision. It defines how quickly steel reaches the site, how reliably the project is delivered, and how well the building performs over decades of use. A strong partnership requires engineering rigor, precise fabrication, and dependable delivery systems. In many ways, choosing the manufacturer is equivalent to choosing the level of certainty you want for your project outcomes.

The Growing Momentum of PEBs

The market momentum for pre-engineered buildings has never been stronger. India’s industrial growth, coupled with global acceptance of prefabrication, has opened applications that extend far beyond warehousing. PEBs are now found in manufacturing facilities, commercial complexes, educational institutions, and even mixed-use retail developments. Their appeal lies in how effectively they solve universal challenges—compressed timelines, reduced risks, and better control over lifecycle costs. Factory fabrication shortens schedules, standardized systems reduce uncertainties, and efficient design lowers energy and maintenance demands. While highly irregular or heavily customized architecture may still require hybrid approaches, aligning a manufacturer’s capability with project needs has proven to be the smartest path forward.

The Pitfall of Chasing the Lowest Cost

One recurring mistake that causes projects to stumble is the pursuit of the lowest upfront cost. Procurement teams under pressure to show savings often award contracts based solely on price. Unfortunately, these savings are short-lived. Inadequate coatings eventually allow corrosion to set in, weak detailing leads to costly repairs, and poor coordination between design and erection teams creates delays on-site. What begins as a low-cost contract often ends up costing more in rework, energy inefficiency, and maintenance over the years. Ironically, the cheapest option often becomes the most expensive outcome.

What Strong Leaders Do Differently

The strongest project leaders understand that true value comes from fundamentals, not discounts. They focus on engineering rigor, ensuring that partners bring not only design expertise but also validated in-house capabilities, compliance with codes, and a culture of value engineering. They prioritize fabrication quality, looking for robust quality systems, certified welding processes, appropriate coating systems for site conditions, and full traceability of materials. They also examine delivery capacity, assessing production lines, throughput, and shipment sequencing, since even the best components are useless if they arrive in the wrong order. Finally, they recognize that the performance of the building envelope—insulation, roofing assemblies, and water or thermal protection—will ultimately determine whether operational costs remain predictable or spiral over time.

Sustainability as a Baseline

Sustainability has quickly moved from being a bonus to becoming a baseline expectation. Clients today demand measurable practices such as recycled content, minimized waste in manufacturing, and certifications that align with global standards like LEED, IGBC, or GRIHA. Manufacturers unable to document their sustainable practices increasingly find themselves disqualified from serious projects. In this environment, sustainability is not just about compliance—it is about responsibility, reputation, and long-term value.

Practices That Ensure Success

For leaders who want to avoid surprises, a few professional practices make all the difference. Evaluating lifecycle costs rather than only upfront capital expenditure helps ensure that energy, maintenance, and downtime are accounted for from the start. Asking for inspection and welding documentation before contracts are signed brings clarity on quality expectations. Reviewing erection safety standards and sequencing in advance reduces on-site risks and protects timelines. These habits may seem simple, but they often mean the difference between a predictable, high-performing building and one riddled with unexpected delays and costs.

A Real-World Example

Consider a 30,000 square-meter coastal warehouse with a strict 24-week deadline and stringent energy performance requirements. One manufacturer offers a lower quote, relying on ordinary coatings, skipping insulated roof systems, and making vague commitments about delivery. Another provides a slightly higher quote but specifies coastal-grade coatings, proven insulated roofing systems, and a detailed shipment plan designed to keep installation on track. Six months later, the choice becomes clear. The client who chose the latter avoids corrosion, maintains predictable energy costs, and achieves on-time delivery. The upfront investment pays off in certainty, reliability, and peace of mind.

Conclusion

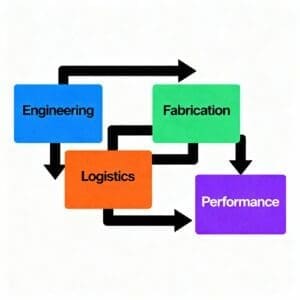

Pre-engineered buildings are not commodities; they are precision systems integrated across design, fabrication, logistics, and erection. Choosing a manufacturer is not simply awarding a contract but building trust in performance and outcomes. With the vendor ecosystem more competitive than ever, project leaders now have the opportunity to be highly selective. By asking deeper questions about engineering strength, quality standards, delivery capacity, and sustainability, organizations can avoid short-term traps and focus on long-term certainty.

In the end, what every organization truly seeks is not just a building, but peace of mind. The right PEB partner doesn’t just construct frames—they build confidence, reliability, and trust into the future of your business growth.